Marine Oil Technology

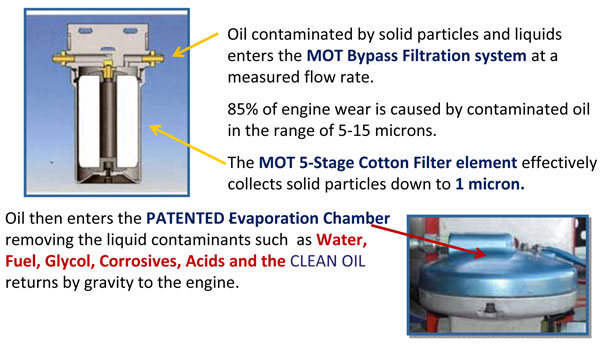

How the Bypass Filtration System for Engine & Hydraulic Oil Works

Oil Contamination

Where do the oil contaminants come from?

By examining the substances in the oil you can find out where in the engine you have a problem.

• Boron (B) – Anti-freeze, fuel with biocides

• Sodium (Na) – Seawater, dust, anti-freeze

• Silicon (Si) – Sand, dust, dirt, glycol-additives

• Barium (Ba) – Oil additives, diesel additives

• Aluminium (Al) – Pistons, bearings, bushings, cylinder liners, dirt, dust

• Chromium (Cr) – Piston rings, cylinder liners, valve lifters, camshaft, anti-freeze

• Copper (Cu) – Bearings, bushings, cooling tubes, copper paste

• Iron (Fe) – Miscellaneous machine parts

• Lead (Pb) – Bearings

• Tin (Sn) – Tin-covered pistons, bearings

• Molybdenum (Mo) – Cylinder liners, piston rings

• Nickel (Ni) – Camshaft, rods

• Titanium (Ti) – Rubber gaskets

• Silver (Ag) – Bearings (needle bearings)

Oil flow and temp

The filter unit and the evaporating unit are built to work as one unit together. To get correct and safe function with the right flow, the oil has to pass through the filter unit before the evaporating unit. The process is driven entirely by the engine’s oil pressure and normal electrical system.

What about Additives?

The oil analysis reveals the amount of additives in the oil sample. A decline of 20% is generally accepted. The following substances are normally included in oil additives:

• Barium (Ba)

• Boron (B)

• Calcium (Ca)

• Magnesium (Mg)

• Phosphorous (P)

• Zinc (Zn)

Additives enhance specific properties of the oil and can be further categorized into sub-groups,

depending on their respective functions:

• Anti-oxidants

• Rust prohibitors

• Dispergents/Detergents

• Anti-wear additives

• EP-additives (Extreme Pressure)

• Anti-foam additives

• VI improvers (Viscosity index)

• Pour-point depressants

• Flow improvers

How to read an oil analysis

Viscosity by 40ºC and 100ºC

Unit: mm2/s

Limit: A variation of +/- 15% is normally accepted

Viscosity decrease

The oil has been diluted by fuel, the oil viscosity helpers have been broken down or the oil has

been topped up with oil of lower viscosity.

Viscosity increase

Large amounts of soot or other contaminations, oxidation products, water that has caused

emulsion or the oil has been topped up with oil of higher viscosity.

Oil Condition Index (OC)

Unit: Graded 0-40

Gives an indication of how contaminated the oil is. Values of 8-11 are typical for new oils. Up to

28 is acceptable for used oil. Higher values can indicate problems with the status of the oil.

Soot

Unit: Weight%

Level of soot in the oil – most engine manufacturers accept values of up to 2.5%.

TBN/TAN

Unit: mg KOH/g

Total Base Number/Total Acid Number -An acid oil can together with water be very aggressive

and cause corrosion. Most engine manufacturers accept a reduction of TBN by 50%.

Water

Unit: % or ppm

Level of water in the oil

Water in oil should be avoided. Water starts the oxidation process and the oil breaks down. More

than 0.2% water (2000 ppm) should not be accepted.

Fuel

Unit: Normal/Caution/Serious

Degree of fuel dilution in the oil.

Glycol

Unit: Normal/Caution/Serious – degree of glycol dilution in the oil.

Flash Open

Unit: Degrees Celsius

Shows if the oils flammability is higher or lower than the stated temperature:

Limits: >195=normal, 195-180=caution, <180=serious

Dispersancy

Unit: Good/Poor. The ability of the oil to keep (soot) particles floating so that they can be filtered

out when the oil passes the oil-filter.

Quick Links

- How the Bypass Filtration System Works

- Testimonial from Latitude

- Testimonial from Parker | Racor

- Testimonial from TraPac

- MOT Specifications

- Mariner Vessel Ships and Boat Engines

- Shipping Port Facilities

- Electrical Generator Facilities

- Cummins Turbo LNG

Downloads

Fairleigh Enterprises

Marine Oil Brochure

Download

Installation Guide

MOT Generic Install Guide

Download – Part 1

Download – Part 2

Download – Part 3

Download – Part 4

Marine Oil Technology. All rights reserved.